Flex-Hone usage

The Flex-Hone can be used manually with a regular drill, on a column drill, within the processing cycle of CNC machines as a tool, or on transfers for industrial applications, even with high production volumes.

• Using the Flex-Hone dry is not recommended as it significantly reduces its lifespan. It is advised to use whole oil with a viscosity between 10 and 30 or an emulsifiable cutting fluid for mechanical operations. A common spray lubricant can also be used, and when working on brake cylinders, hydraulic brake oil is recommended. Diesel, petroleum, or solvents-containing

lubricants can be used but are not recommended as they reduce the Flex-Hone’s lifespan by breaking down its abrasive balls more quickly.

• The Flex-Hone works under pressure, so its effective diameter is larger than the bore to be worked on.

• The Flex-Hone MUST enter and exit the bore in rotation.

• The Flex-Hone is NOT balanced; DO NOT spin it at maximum speed before it has entered the bore to be worked on.

• Consult the table for choosing the correct rotation speed in relation to the diameter; however, the rotation speed may vary depending on the application. It is recommended to conduct tests and use the Flex-Hone with the shortest contact time that achieves the desired result to maximize its lifespan. High speeds cause premature wear without achieving appreciable time reductions. DO NOT use high-speed tools. For manual use, use a regular electric drill.

• Operate with rapid reciprocating movements with a frequency of 60 to 120 strokes per minute depending on the rotation speed. Accelerate the alternation of strokes at the end of the operation to achieve a cross-hatch pattern of 30°-45°.

• The processing time should be approximately 20-45 seconds for each cylinder in the case of a motor application, but it may vary depending on the material, application, abrasive, grit, and lubrication.

• Wash the cylinders thoroughly after processing and lubricate with oil.

• The lifespan depends on various factors such as the abrasive used, lubrication, material being worked on, whether it is used with a machine or manually, the length of the bore, contact time, etc. Several hundred to over 1000 pieces can be processed with a single Flex-Hone.

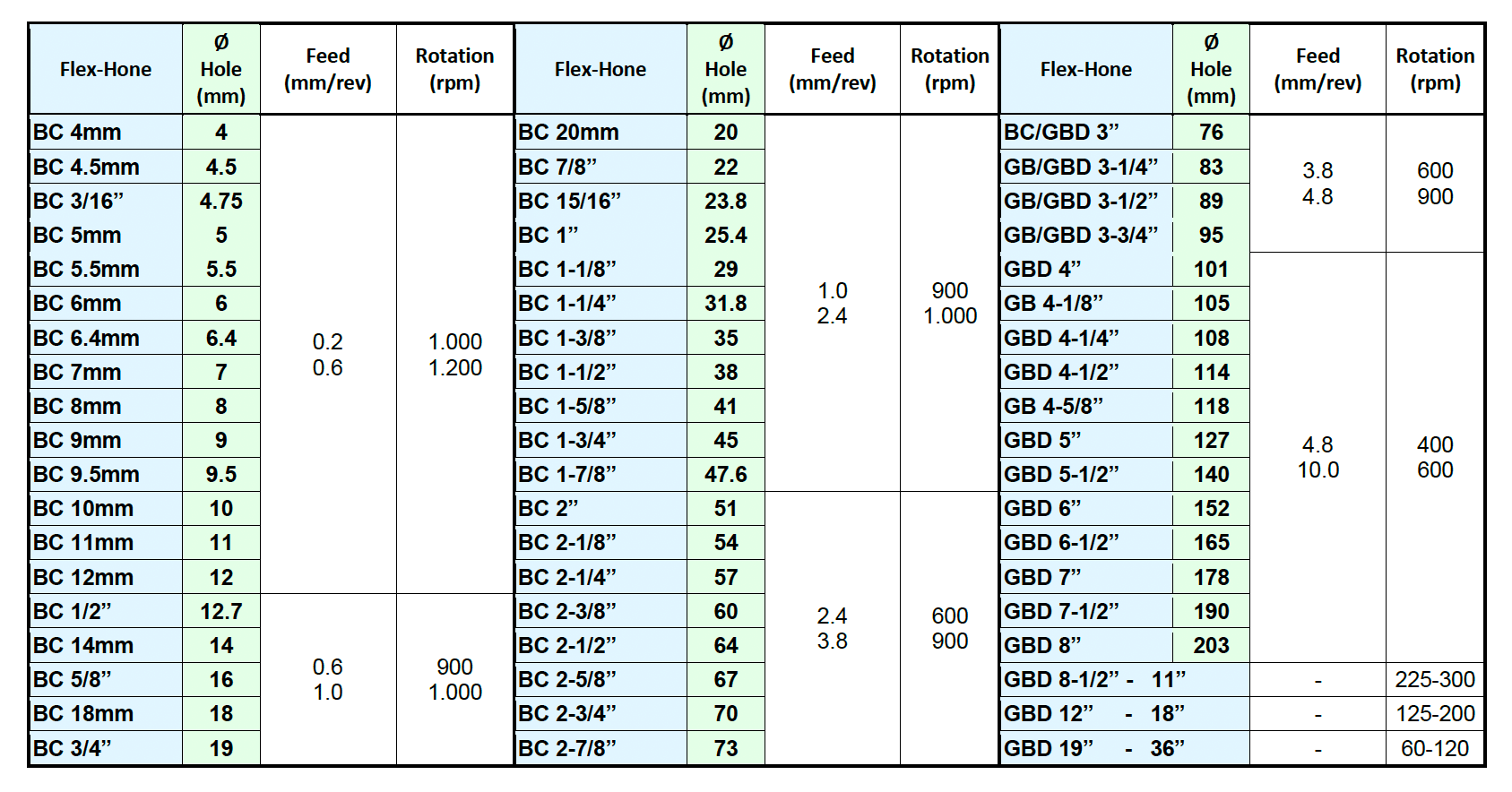

Speeds and feeds

The Flex-Hone is a low-speed, high-feed tool. The rotation speed depends on the diameter and application. Below are indicative values, but some processing tests are still necessary to find the correct speed. The feed rate of the Flex-Hone depends on the diameter, working length, and desired cross-hatch angle in the typical cross-hatch finish. Indicative parameters can range from 2500-3000 mm/min for medium to large diameters up to 6,000 mm/min for small diameters. When used on CNC machines, a maximum indicative value can be taken as 5% of the diameter. Below is a table with some examples.

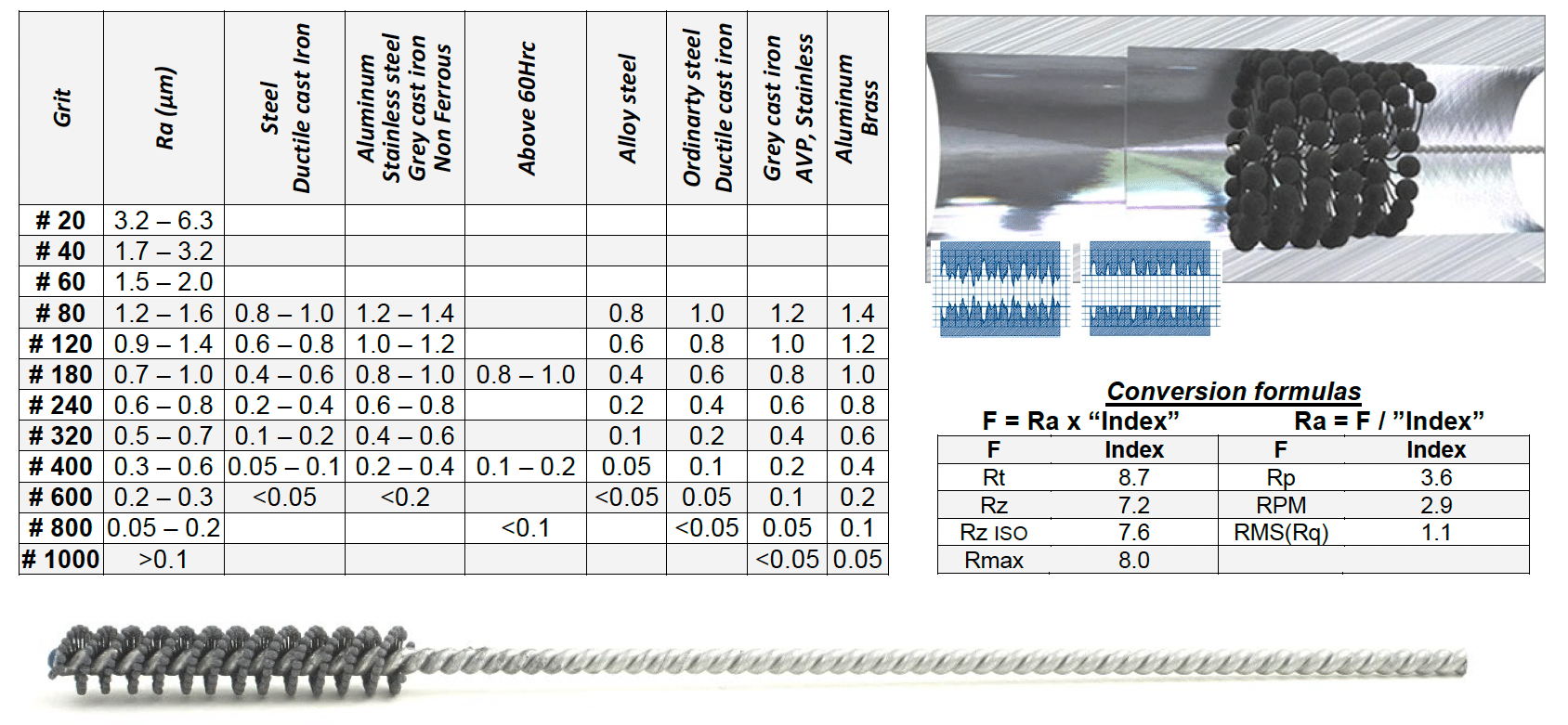

Grit / Finish selection Table

The values are for informational purposes only, as the achievable Ra is influenced by multiple factors such as the nature and hardness of metals, type of lubricant used, contact time, previous machining, Ra before Flex-Hone, etc…